Table of Contents

Just like with any other type of art, making jewelry requires time and considerable talent. And if you are asking, ‘Who can make my jewelry?’ Here is the answer.

Each piece of jewelry needs to be conceptualized by the designer while considering all the potential methods and limitations of the production process. Then it needs to be transformed into lovely items we can sell and wear.

Jewelry used to be manufactured by hand; metals were all formed into desired shapes, and each gemstone was painstakingly placed by hand.

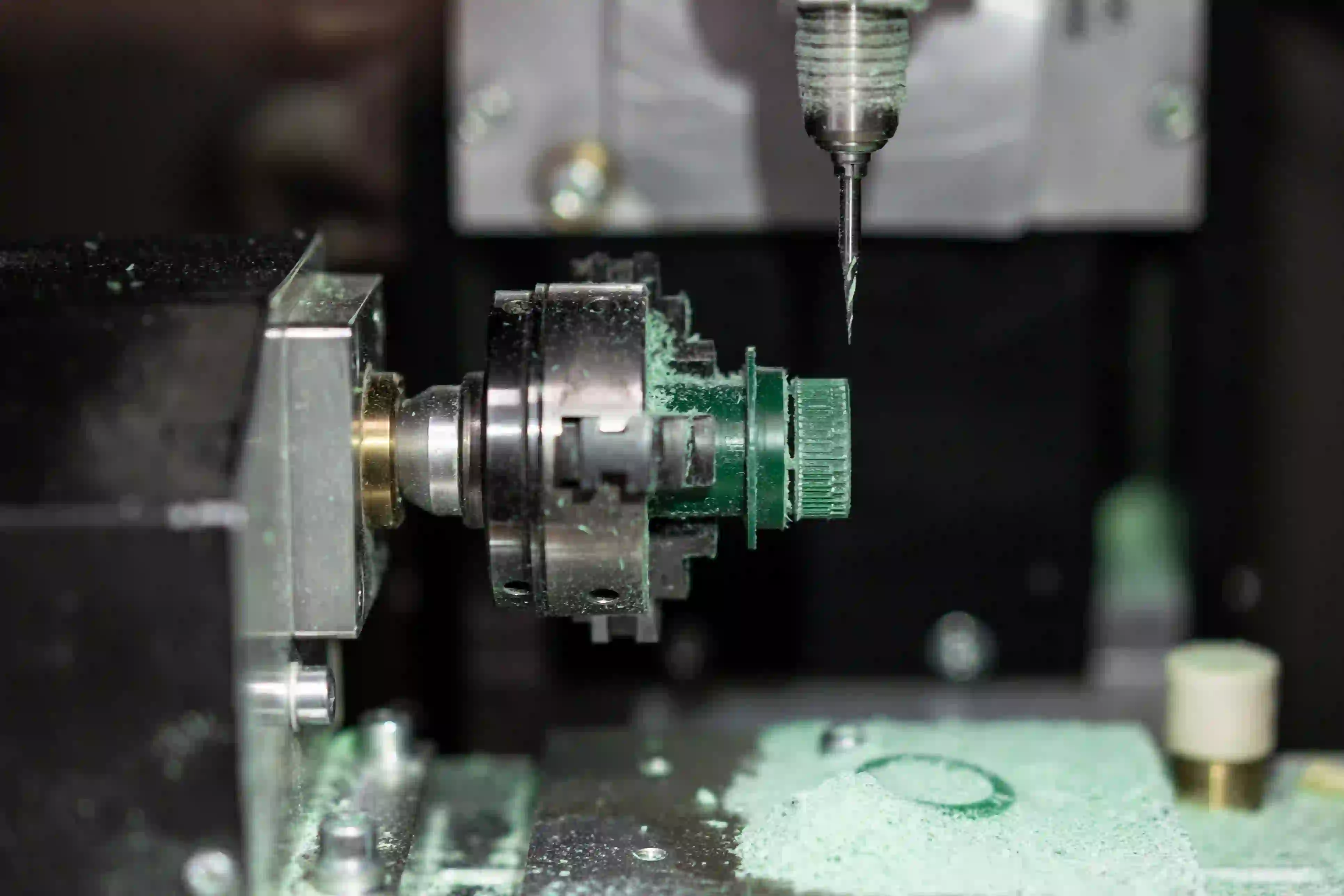

Bench jewelers and other artists are now equipped with various tools and technologies to enable them to create each of their creations quickly and easily through technological breakthroughs.

The term “jewelry manufacturing” refers to a fairly broad topic that covers everything from simple assembly to making custom jewelry.

If you do not know, jewelry is created by soldering or fusing precious metal segments or components into place. The heads, cages, or prongs required for setting gemstones are just one example of a component used in jewelry production. Other functional components include clasps, clutches, and earring posts.

In this article, other areas of jewelry design manufacturing will be examined. Such areas include finding manufacturers, prototyping and sample production, manufacturing process, how to outsource jewelry, how to find jewelry and so on and so forth.

There are many questions that people ask. Questions like, how to get my jewelry designs, how to outsource jewelry, how to find a jewelry, who can make my jewelry, best ways outsourcing jewelry and many more.

All these questions, and many more, will be answered in this article. Stay put and enjoy a bumpy ride.

What is Jewelry Design Manufacturing?

Bench jewelers assemble individual components and combine them into a finished jewelry item as part of jewelry fabrication. A jeweler is frequently required to solder, weld, or solder pieces of precious metal with different hues as part of the procedure.

Jewelry creation and manufacturing always require components, setup, and bonding. Sometimes, jewelry casting makes the parts that must be fabricated. The raw castings are rough until they are shaped and completed by a trained artisan, even though the cast items are made from precise CAD jewelry designs.

Cleaning and deburring of cast goods is a crucial part of jewelry manufacture. Cast components will interlock with the model when assembled, thanks to careful preparation.

In other cases, raw metal is rolled or drawn into sheets and wire is used to create the pieces. To generate settings or details that can be incorporated as design elements, wire and plate can be soldered or welded together. Jewelers can mould raw metal to form the design elements required as appliqué to models using files, gravers, and rotary grinding equipment.

How to Get My Jewelry Designs

A few alternatives exist to get your jewelry designs made in large quantities. One choice is to pay your employees to produce many duplicates of your designs. Another choice is to contract with a business specialising in this kind of manufacturing to produce your ideas in bulk.

It is frequently advised to outsource your production locally because it is simpler to resolve any problems with mass-producing your goods, perfecting your products, and figuring out your procedures.

You can look for local people who can help with your production if you only need a few people to assist you with simple chores like assembling, hand-tool work, and packaging.

Finding someone eager to assist you with your production job might be found through networking with other jewelry designers or artisans in your neighborhood. Another choice is to go to a design center, where you can investigate all the options for making unique jewelry. A jewelry design form can be used to express your ideas or ask for help with the design.

To learn more about the creation process, you may also speak with a jewelry designer. Remember that your individual requirements and corporate goals will determine how you obtain your jewelry designs.

It’s crucial to consider aspects like cost, scalability, and how much time and effort you want to devote to the production process.

How to Outsource Jewelry Production

How to create and make your jewelry is a very crucial issue for jewelry designers or online shop owners, so how do you outsource your jewelry production?

The best way to outsource jewelry manufacturing and production is to pick a trustworthy factory.

The cost is the primary element in picking factories overseas. Profit is, after all, the most crucial aspect of the store owner’s business. A good overseas manufacturer can provide high-quality goods and the appropriate price to give you a competitive edge in the marketplace.

Read More:

1. Know the location of the factory

For instance, silver jewelry is sold worldwide in nations like Canada, South Korea, Thailand, and China. Prices, supply, and product quality fluctuate between factories from various nations. Some are fashion jewelry, some are fine jewelry, some are inexpensive, and some are pricey, with varying levels of quality.

Researching the quality of silver items in other nations is crucial when comparing silver pricing. The item that best suits your target market is only sometimes the one with the lowest price. The most straightforward way to determine the product’s quality and learn more about the pertinent details is to purchase a sample. Naturally, it relies on everyone’s strategy.

2. Know the strength of the factory

Outsourcing jewelry production to companies should be easy if you know the following things about the company.

– Know the factory’s workers population.

Less than 20 is considered as a small factory. There are 20 to 100 workers in the medium-sized factory. More than 100 employees work at large factories. Any of these companies can help you achieve your aim.

– Determine each factory’s level of jewelry manufacturing experience.

You can locate suppliers who will provide you access to their catalogs, and you can assess the suppliers’ qualifications and experience based on the catalogs.

– Whether a design team is present.

The design team is pricey. However, a factory with such team will frequently help you cut down on many design and manufacturing issues and can even offer production guidance for your jewelry.

– The presence of expert producing equipment.

Production equipment like a wax injection machine, a laser printer, a grinder, etc. Vernier calipers and electronic balances are examples of testing equipment.

– Understand the factory’s production techniques.

The two primary categories of silver jewelry craftsmanship are simple jewelry craft and fine jewelry making. Prices for various craftsmanship vary as well. The jewelry created by superb jewelry artisans will look considerably more lovely than jewelry created by ordinary jewelry artisans.

In all of these, choosing a manufacturing and production company that provides a private label service is important. Yehwang is a top-rated jewelry manufacturer that you can rely on for the best production of jewelry that you like.

How To Find A Jewelry Manufacturer

A trustworthy manufacturer is the cornerstone of any jewelry launch that is successful. Many business owners shop around with different manufacturers before settling on one.

It’s challenging since there are so many options available, and naturally, everyone will position themselves as the greatest choice.

Making decisions rather than relying on others to tell you what you need or don’t need from a manufacturing arrangement is the key in this situation.

1. Know What You Want

There are a few things to consider when searching for a fine jewelry factory. As each brand is unique, so will be the circumstances under which you begin your search for a manufacturer.

For instance, are you already a successful brand trying to grow? If not, you might have a newer business with a lower prospective order volume. Know what you want; it will help you find a jewelry manufacturer that matches your interest.

2. Check For Product Quality

You already understand the significance of quality if you’re creating a line of exquisite jewelry. Your customers will be more impressed and inclined to become returning consumers if the quality is higher.

This is something to take seriously because recurring business is one of the best methods to grow any business. A good product’s quality could encourage customers to buy it again, and it’s much more difficult to win back a dissatisfied customer. Products of gold vermeil, plating, and filling are not all created equal.

When you check for these two factors, you can find the right jewelry manufacturer that catches your fancy.

Read More:

- How to Become a Jewelry Distributor: A Step-by-step Guide

- How to Start a Small Jewelry Business from Home

- How to Start a Jewelry Line with No Experience

Conclusion

Recurring customer is a crucial component of growing your company, and you won’t have a chance of obtaining it if you don’t research and choose the best jewelry manufacturer. You could lose money while sourcing, which might be a tedious effort before you find the appropriate fit. Consider your selections using the following tips rather than wasting your precious resources.

Read the post again if you want to know how to make exquisite fine jewelry that will attract repeat business tenfold at affordable pricing. At the end of the day, if you care about quality, we make it our mission to realize your vision.